Why are piezoelectric buzzers in demand?

Piezoelectric materials produce electric signals when under mechanical stress. The process is reversible, that is it can produce mechanical output if electric signal is given as input. When electrical signal is given to these materials, they change their shape slightly. Let us dive into more details about this amazing part of machinery.

What is a piezo buzzer?

As the name suggest piezo buzzer is an electronic product that is used to produce a tone, alarm or buzz. Its light weight and simple in construction and low cost. Depending on the piezo ceramic buzzer specification its highly reliable and can be used in wide range of applications in varying sizes & frequencies.

Our piezo buzzers offer high sound output, also as they can be mounted on circuit boards they can be used in wide range of applications & assemblies. All our prices are highly competitive with fast delivery time.

How is piezoelectric buzzer used?

The piezoelectric property was discovered by Pierre Currie & Jacques in 1880, when they found that some of the materials when applied with electric signals can produce mechanical output and vice versa.

When a piezoelectric material is subjected to alternating current, it stretches and compresses in sequence with the frequency of current and hence produces and audible sound.

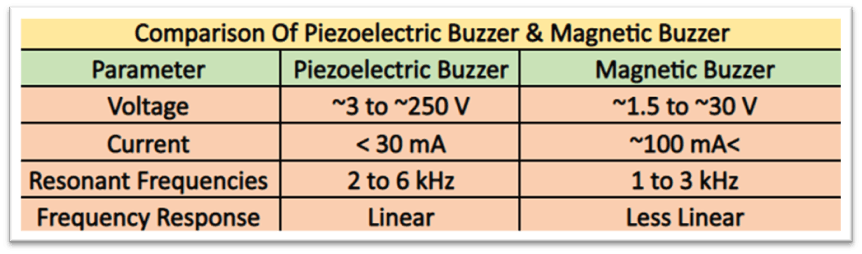

Piezoelectric buzzer work in a voltage range of 3-250 V unlike magnetic buzzer which has a narrow operating range of 1-16 V. The power consumption also piezo buzzers are less than 30miliamperes, even at higher frequencies whereas for magnetic buzzer it may range from 30mA –100mA. These are some of the primary reasons why piezoelectric buzzer is preferred over magnetic buzzers.

Applications Of Piezo Buzzers

Piezo buzzers are flexible and reliable due to which they produce monotone buzz to multi tone alarms hence they find huge application in small & high-density applications. Due to their low power consumption, they can be easily used in batter operated devices. So, in short, they are used in applications like alarms, warning devices & automobile alerts. Their wide range of audible signals find them applications in pest controlling devices. They also are used in computers, toys, games etc.

Audible Sound Transducers

Also called tone generators, these simple, compact, reliable piezoelectric audible sound transducers can produce high sound output from a small energy input. They are widely used in battery operated devices, timers, smoke alarms, telephone ringers, metal detectors etc.

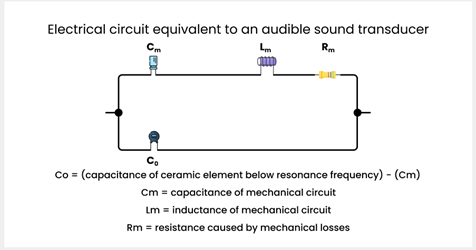

Audible sound transducers consist of a thin disk of piezoelectric ceramic bonded to a thin metal diaphragm. When voltage is applied to the ceramic disk it deforms causing the metal diaphragm to bend and produce sound. Likewise, when a recurring voltage is applied to the ceramic disk the metal vibrates at frequency equal to the applied voltage and produces sound. The maximum sound is produced when the mechanical resonance frequency of the metal matches the frequency of electric signal applied.

The future Of Piezoelectricity

The piezoelectricity is an interesting part of nanotechnology and many tests are underway to harness its power in full form. If used well and in right direction piezoelectricity will be another technology with which we can reduce our dependency on fossil fuels to produce the amount of energy we need.